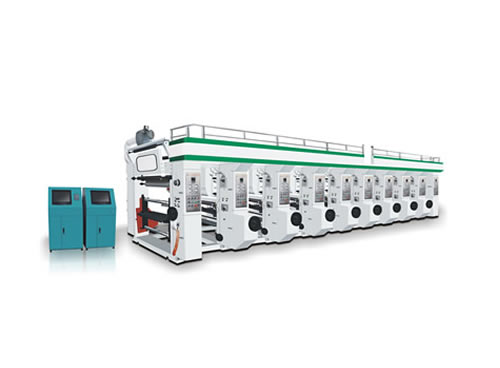

YTB-8600/8800/81000 High speed 8 colors Flexographic Printing Machine

| YTB-8600/8800/81000 High speed 8 colors Flexographic Printing Machine |

| Categories: Printing Machine Series |

| Tel: 0086 577-66817170 |

| Mobile: 0086 15858567170 |

| Email: rahsjx@rahsjx.com |

| Songjiadai Industrial Zone, Feiyun Street, Ruian city, Zhejiang,CHINA. |

1.Feature

1)Ink Roller :With the Ceramic roller by 200LPI-1000LPI.high speed dot reproduction rate ,screen printing, structure three –dimensional sense of strong ,registering accurately

2)Ink :Adopt the automatic circle system ,running ink by single small motor

3)Timing :Adopt Japanese inverter controlled ,running by small fluctuations

4)Unwind EPC :adopt the high quality automatic EPC controller device

5)Unwind and rewind way : adopt the magnetism Auto tension controller.

6)Ink way :our company has special design for the doctor blade device with the ink pump can suck the ink automatically

7)Up and down plate :adopt the hydraulic pressure rising and down the printing plate automatically

8)Roller :adopt the special steel processing ,and through the special technique treatment , and plating thickness of 10 silk protective layer of hard chromium, beat the following in the 0.02mm

9)Traction Rollers :adopt Japanese production of small semi-enclosed bearing, static equilibrium and dynamic levels do cross-processing, hard oxidation treatment, resistance, beating a small

10)Drying device: ventilation with heat blowing three devices, which use a central heating temperature control system and the control each group

11)Body: thick wall (75mm), longer bridges, thick base, making the machine more stable.

2.Main Technical Specification

2.1 Main parameter

Model

YTB-8600/8800/81000

Max unwind width

600mm/800/1000mm

Max. Effective print width

560mm/760mm/960mm

Material

Non-woven fabric:15-120g; Paper:15~400g;

PVC:15~120μm; OPP:10~100μm; BOPP:10~100μm; PE:15~150μm; NY:15~120μm; PET:15~100μm

Printing color

8 colors

Max.Length of Printing

200-1100mm

Machinery mechanical speed

10-120m/min

Max.Speed of Material Printing

10-100m/min

Rubber plate thickness

2.38mm

Total power

40kw

machine weight

6700kg

machine dimension

5.2×2.0×3.3M

Power condition

380V,3PH,50HZ/220V,3phase,60HZ

2.2 Unwind Unit

Max.unwind roller width

1500mm

Max.effective length

600mm

Max.Unwind diameter

¢800mm

Type of Unwind

auto tension with magnetic powder

Unwinder Magnetism device

5kg

Unwind auto tension controller

2—20kg

Unwind EPC system

Electrical EPC system

Feeding shaft

Air shaft

Axis core diameter

76mm

2.3 Traction Unit

Constitution of Traction

Aluminum roller,Chrome plated Roller

Traction Zones

8Zones

2.4 Printing Unit

Constitution of Printing

Anilox roller, Rubber roller, Chrome plated roller, Version roller Resin version, Scraper

Girth of Pressing Roller

200-1100mm

Material of Plate

Resin or Rubber

Principle of Work

Gears Drive

Adjusting of Register

Manual

Overprint Precision

Horizontal:+-0.15mm,Vertical:+-0.2mm

Plated-glued roller adjusting

hydraulic type of plate-cylinder

Anilox Roller

Ceramic Anilox Roller:1 pcs/per color

Rubber rollers

1 pcs/per color

Scraper

Ordinary

2.5 Heating and Drying Unit

Type of Heating and drying

blowing first then heating

Heating Zones

12 zones

Power of Heating

12kw

Assistance of Drying Length

2m

Blowers

8 Fans

Power of Blowers

1.5kw×2pcs; 0.2kw×6pcs

2.6 Electrical Parts

Main motor

3.7kw

Ink-Transfer Motor

0.2kw

Inverter

3.7kw

Tension test

2--30kg

2.7 Wind Unit

Max. Rewind roller width

1500mm

Max. Rewind diameter

¢600mm

Type of Wind

Auto tension with magnetic powder

Rewinder Magnetism Powder

5-10kg

Collect Reducer Motor

1.5kw

Auto tension controller

2—20kg

The receiving shaft

Air shaft

Axis core diameter

¢76mm

-

YTC-4600/800/1000/1200 high speed 4 colors CI type flexographic printing machine

-

YTB-8600/8800/81000 High speed 8 colors Flexographic Printing Machine

-

HS-850 PP Woven/Non woven Fabric Bag Printing Machine

-

BY Series Adhesive Label Flexographic Printing Machine

-

ASY-M Series Computer Middle Speed Gravure Printing Machine

-

ASY-A Series Normal Speed Gravure Printing Machine

-

YT-6600/800/1000/1200 Middle Speed 6 Colors Flexographic Printing Machine

-

YTB-6600/800/1000/1200 High Speed 6 colors Flexographic Printing Machine

0086 15858567170

0086 15858567170

Message

Message